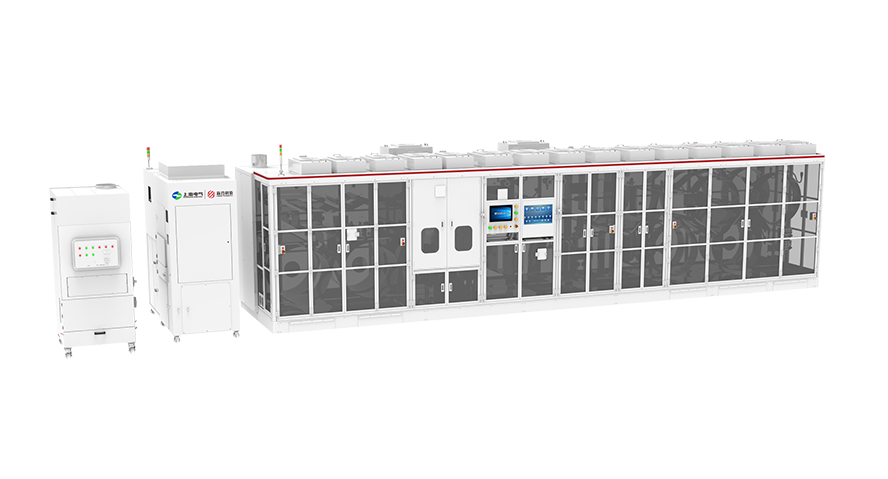

Laser notching and slitting integrated machine

Linear speed:

Max. 120m/min

Electrode thickness Specification:

60-250μm

The equipment adopts globally renowned brands of lasers, galvanometers, and F-theta lenses, combined with advanced laser control algorithms to achieve real-time speed and energy tracking during cutting, ensuring consistent cutting quality. For many years, we have been dedicated to the research of customers’ cutting processes and dust control. We've developed a variety of dust removal solutions — including convective three-dimensional dust removal, vertical cutting dust removal, super air knife dust removal, and brush dust removal, providing customers with more thorough dust removal solutions!

Equipment Parameters

Equipment model | YHLC800A |

|---|---|

Overall line dimensions (mm) | 8000(L)*2300(W)*2800(H) |

Operating line speed(m/min) | 60-120 |

Laser cutting burrs(μm) | ≤10 |

Electrode slitting burrs(μm) | ≤7 |

Electrode width specifications(mm) | 150-500 |

Reel diameter specifications(mm) | ≤1000 |

Electrode slitting error(mm) | ±0.2 |

Accuracy of tab cutting position(mm) | ±0.2 |

| Accuracy of tab shape cutting(mm) | ±0.2 |

Accuracy of correction control(mm) | ±0.1 |

Accuracy of Mark hole position(mm) | ±0.3 |

Electrode thickness specifications(μm) | 60-250 |

Foil thickness specifications(μm) | 4.5-20 |

Dust removal effect | 10000-level Cleanliness |

Related Products