Prismatic power battery laser and winding integrated machine

Efficiency:

6ppm(Length of electrode: 16m)

Linear speed :

Max3000mm/s

This equipment integrates laser tab forming and automatic winding. Its main functions include automatic roll changing, multi-stage dust removal for electrode, laser cutting of tabs, CCD defect detection, application of protective adhesive tape to the front and end of the cathode electrode, CCD Overhang detection, round needle winding and unloading, application of terminal adhesive tape, cold pressing and shaping of the cell, Hi-pot testing, and CCD appearance inspection of the cell. With the support of advanced algorithm control, it enables closed-loop adjustment of tab spacing, segmented automatic tension control, and closed-loop alignment control of the winding process.

Equipment parameters:

Equipment Parameters

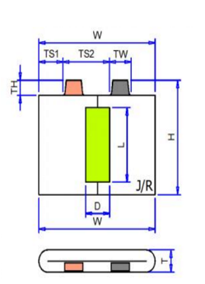

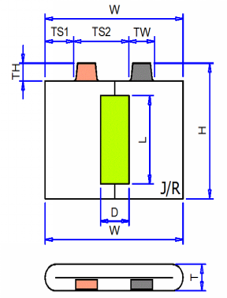

Equipment model | YWPB300K | Cell diagram |

|---|---|---|

Compatibility range | H:60-280mm; W:80-320mm T:10-40mm; TH≤40mm |  |

Tab misalignment(mm) | ≤±5 | |

Tension fluctuation | <±3% | |

Laser cutting burrs(μm) | <10 | |

Efficiency | 6ppm (Length of electrode: 16m) | |

| Qualification rate | ≥99.5% |

Related Products