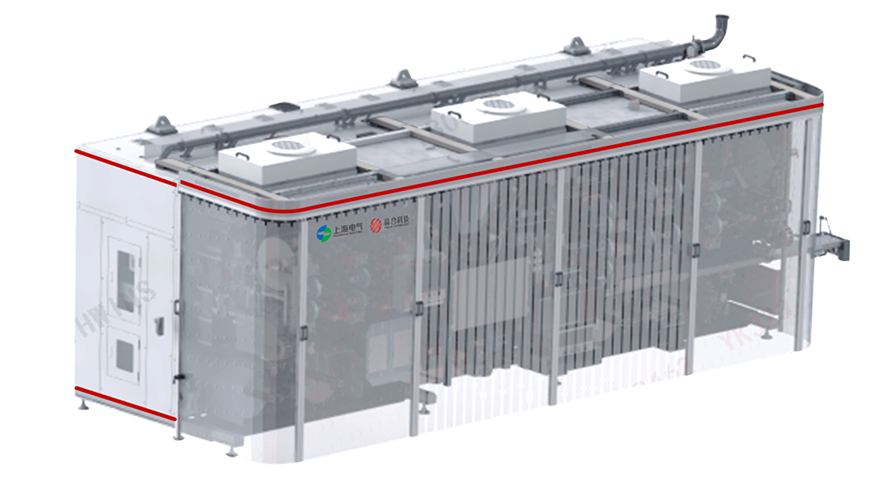

3C electrode-making integrated machine

Efficiency:

>21PPM/min

Yield rate:

≥99.5%

This equipment is suitable for the fully automated winding of prismatic 3C lithium-ion batteries. It features CCD online detection of various data and closed-loop control. After the cell flattening and Hi-pot testing, the cells are unloaded from a conveyor belt.

Equipment Parameters

| Series/Item | 60Series | 160Series |

|---|---|---|

Cell height(mm) | 10-60 | 40-160 |

| Cell width(mm) | 8-30 | 30-110 |

| Cell thickness(mm) | 2-6 | 2-10 |

| Mechanical speed (m/min) | Constant linear speed ≥600mm/s | |

Winding mode | Outer packing by separator/electrode | |

| Efficiency(PPM/min) | >21PPM | |

| First-pass yield | 99.5% | |

| Alignment(mm) | ±0.3mm,CPK>1.33 | |

| Tab margin (mm) | ±0.3mm,CPK>1.33 | |

| defect detection | CCD detection + short circuit | |

| Optional configuration | Tab welding: Laser welding / ultrasonic welding / triple tab / no welding Taping: Anode 4, Cathode 6/ Anode 6, Cathode 8/ Anode 8, Cathode 10/ No taping Winding process: Central tab / triple tab / conventional process | |

Related Products